This one two punch delivers new buildings quickly and economically which might explain why more than 650 million square feet of tilt up buildings go up every year.

Pros and cons of tilt up concrete walls.

Admittedly the tilt up method requires more up front coordination and changes to the design once the panels have been constructed can be costly.

Precast concrete wall advantages.

Tilt up construction has increased in popularity from the 1920s when it was invented as a building method.

The cons of tilt up for architects.

Approximately 15 percent of all industrial buildings within the u s.

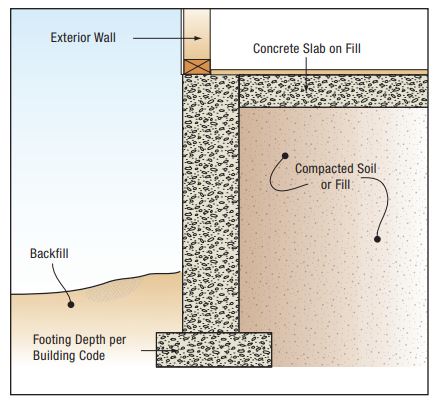

The panels are mixed either on a work platform or directly over the floor slab of the structure and are then lifted with a crane and placed over the foundation.

It s cost effective 2.

It is a construction system that consists of thin on site made concrete walls which are further divided into sections that are called panels.

The pros of tilt up construction.

This method required.

Tilt up s concrete walls provide increased durability and security against weather and operations minimizing maintenance and prolonging the life of a building.

Your builder should be able to provide you with the pros and cons of your chosen material to help you make the most informative decision.

Precast concrete walls assure you of high quality and resilience.

Combined structure and cladding where a hard wall is desired metal buildings provide the exterior structure only and require separate cladding for a completed shell adding cost.

There are many reasons why tilt up walls are such a.

While the benefits of tilt up design are many its cons are few.

The walls are also reinforced with steel rods which produces a strong building.

Have been erected using tilt up walls with these buildings all being constructed for various uses and in various sizes.

Form liners old style 4.

Tilt up construction combines the strength and durability of reinforced concrete with the precision and efficiency of the design build methodology.

With tilt up concrete the wall panels are also cast but the casting is done on site.

Tilt up construction speed.

The texture wall colour finish grooves and curves can all be constructed onsite.

The builder can custom design each panel to the client or architects desire.

Digital form lines with photo imaged textures 4.

It can be finished in a variety of ways.

Smooth face down with revels 2.

This article discusses the pros and cons of tilt construction.

Exterior and interior walls can all be poured at the same time.

Tilt up wall construction has been around for quite some time and remains one of the most recommended construction methods for commercial buildings.

Introducing the tilt up method.