When a hatch is left in the open position personnel working atop a roof can lose their footing trip over the hatch s curb or even step backward into the areaway without looking thereby sustaining debilitating or even fatal injuries.

Osha roof hatch size requirements.

Either a deflector plate can be added to the back edge of the opening at an angle of 60.

A common size of roof hatch is 36 x 30 for ladder access to the roof however that size does not meet this osha standard.

2 ladder safety 1926 1053 3 fall protection training requirements 1926 503 4 eye and face protection 1926 102 5 general scaffold requirements 1926 451 6 general safety and health provisions 1926 20 7 head protection 1926 100 8 fall protection systems criteria and practices 1926 502.

1910 23 d 9 when a fixed ladder terminates at a hatch see figure d 3 of this section the hatch cover.

With the required clearance behind the ladder of 7 that leaves only 29 of clearance for the operator to climb through.

Or personal fall protection.

Osha 1910 28 b 1 i 1910 23 a 4 ibc1015 7 roof access.

07 12 2000 1910 23 osha requires fall protection for elevator work when a fall hazard is present.

1910 23 open roof hatches should be protected.

The minimum size cross section of grab bars is the same size as the rungs of the ladder.

Except as provided elsewhere in this section the employer must ensure that each employee on a walking working surface with an unprotected side or edge that is 4 feet 1 2 m or more above a lower level is protected from falling by one or more of the following.

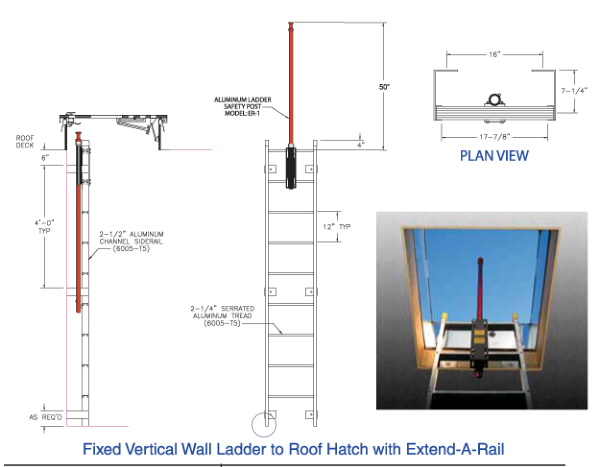

As seen in the picture below featuring new ladder system we recommend a wider climbing surface to accommodate a ladder lifeline system and to make the ladder easier to climb.

Grab bars not required at hatch exits.

Per osha 1910 23 b 4 ladder rungs steps and cleats have a minimum clear width of 16 inches measured before installation of ladder safety systems for fixed ladders.